Nemak highlighted its own competitive advantages in the manufacture of high-tech aluminum automotive components.

In general, the company uses various casting technologies for the production of its products, including the injection or casting of molten aluminum into a mold.

Founded in 2007 as a subsidiary of Grupo Alfa, Nemak also has extensive experience in machining processes.

With year-on-year growth of 7%, Nemak’s revenues were US$4.993 billion in 2023.

After reaching a net income of US$50.6 million in 2022, this indicator was US$4.4 million in 2023.

What are these competitive advantages?

- Generally, the development of know-how takes long periods of time and Nemak believes that its technological expertise gives it an advantage when competing for new aluminum programs.

- The components that Nemak produces are highly complex and therefore of high added value.

- The company offers its customers the most appropriate technology for the design and production of its components.

- Nemak’s collaboration with its customers in the early stages of design and engineering for product development generates an important relationship with them.

Nemak’s customers

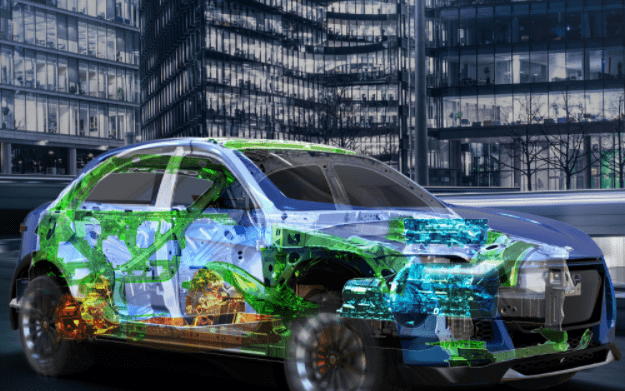

Some of the products produced by Nemak undergo casting and assembly processes, such as certain battery casings for hybrid and all-electric vehicles.

In these cases, certain components are welded to the battery casings using different technologies, such as riveting and friction welding, among others.

Fully assembled battery casings, i.e., casings without castings, are also manufactured.

This process consists of gluing, welding and mechanically joining dozens of individual components, all made from different materials and manufacturing processes other than casting, such as stamping and extrusion.

The company has a portfolio of more than 60 customers, including some of the world’s leading automotive groups and their subsidiaries, such as Audi, BMW, Ford, GM, Hyundai-KIA, Jaguar Land Rover, Mercedes Benz, Porsche, Renault-Nissan, Stellantis, Volkswagen Group and Volvo.

It is estimated that, during 2023, Nemak supplied more than 200 different components for engines, transmissions, chassis and structure components and electric vehicles, which are used in approximately 520 vehicle platforms in production or in the development stage out of approximately 1,550 vehicle platforms worldwide.