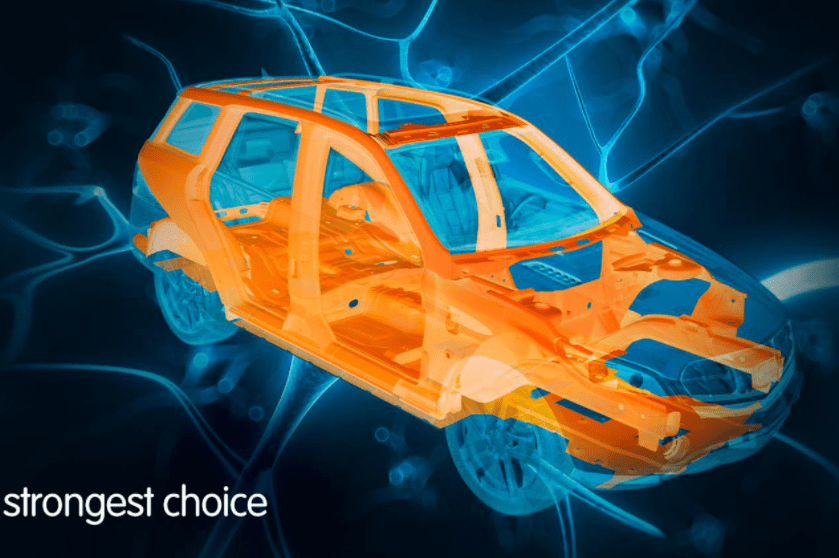

In the trade-off of the grade of use of steel vs aluminum, ArcelorMittal expects that steel will remain the dominant body metal for the growing electrified vehicle market.

In 2020, ArcelorMittal celebrated the 10th anniversary of S-in Motion. This concept has proven to adapt to the changing needs of the automotive market, and its most recent developments in 2019 include a catalog of solutions for the booming electrified vehicle market.

The company’s S-in Motion projects for hybrid vehicles, battery electric vehicles (VEB) and battery packs are already being implemented.

A specific S-in motion project dedicated to the chassis of electric vehicles has also been developed.

This, according to ArcelorMittal, shows that the best steel solutions can be as light as aluminum while reducing CO2 equivalent emissions by up to 58 percent.

So which is the choice: steel vs aluminum. The results of the ArcelorMittal S-in motion VEB study on a sport utility vehicle demonstrated why steel is expected to remain the dominant body metal for the growing electrified vehicle market.

For the company, the steel will allow OEMs to achieve the goals of creating lighter vehicles with higher driving ranges in a more cost-effective manner.

Steel vs aluminum

More than ever, says ArcelorMittal, steel is the material of choice for automotive customers, combining the ability to meet stringent passenger safety expectations with the best price on the market.

As the total life cycle emissions of EBVs are expected to decrease compared to internal combustion engine vehicles, the carbon incorporated from EBVs from metal production and its end-of-life impacts will be increasingly most relevant.

A full Life Cycle Assessment (LCA) study covering vehicle production and end-of-life phases has been conducted on the company’s VEB S-in motion.

It concluded that while the light weight still improves the life cycle performance of VEBs, the gains in powertrain efficiency will have much greater benefits.

The most sensitive aspects of the BEV life cycle are the environmental footprint of battery production and that of the electricity grid. The current impacts of battery production are greater than those of steel body production.

For VEBs to meet legislated CO2 targets, the electricity grid must decarbonize much more quickly.

Between 2000 and 2015, the network decarbonized at a rate of 2 percent.

For large cars to meet CO2 targets, progress will need to triple by 2035.

Life cycle analysis

ArcelorMittal operates 12 research sites around the world, and in 2020, ArcelorMittal’s R&D spending was $ 245 million (compared to $ 301 million and $ 290 million in 2019 and 2018, respectively).

Among its R&D initiatives, ArcelorMittal has developed a 15-year experience in LCA, which analyzes the environmental impact of products during their production, use and disposal.

In 2020, the company conducted a total of 28 LCA studies related to steel products and the processes used to produce them, all guided by the corresponding standard (ISO 14040-44).

![]()